Optikam & Digital Free-Form Lenses

What are Digital Free-Form Lenses?

Think about the first time you saw high-definition television. Remember how it made your old analog TV picture seem dull and blurry? Now imagine having the same experience with your eyeglasses. Sure, you can probably see fine with the ones you have, just like watching analog TV was fine when that was all you had.

Traditional progressive lenses are produced using pre-molded templates and the same design is used for every wearer. Digital Free-Form lenses are customized for each wearer’s prescription. Free-Form is a digital manufacturing process that uses computer-aided design and manufacturing to create customized eyeglass lenses. Think of it as a tailor for your lenses. Just like you can take an off-the-rack pair of pants and have it customized to fit your specific measurements, you can now have lenses customized for your specific prescription and frames. These lenses provide:

- Sharpened vision

- Brighter colors

- Improved contrast

- The widest field of view possible

- Better peripheral vision

- Reduced glare and halos night

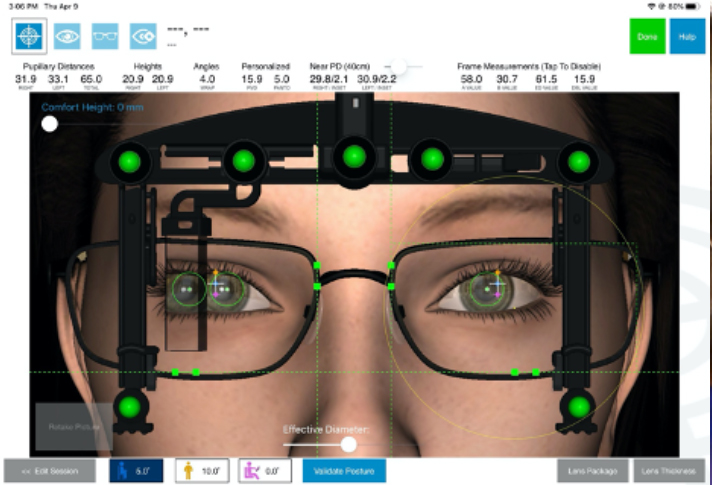

What Measurements Does Optikam Take?

Traditional tools, such as a ruler and sharpie, used to measure lenses limit your lens quality. The Optikam takes additional measurements required for Digital Free-Form lenses including:

- Patient’s posture

- How the frame will be worn by the patient

- The shape and size of the frame

- How close the frame sits to the front of your eye

- How the frame wraps around your face

- How you tilt your head.

- The lenses position in front of the wearer’s eyes in the eyeglass frame to provide the most accurate lens power.

- The position of the wearer’s pupil within the frame outline.

- The angle between the eye and the back surface of the lens in different gaze positions. This angle allows for changes in the lenses power in the periphery of the lenses to compensate for when the wearer is looking off to the side rather than straight through the center of the lens.

These data points are sent to the lens manufacturing lab and plugged into a computer-driven, free-form lens generator. The generator can creates an exact prescription written to 1/100th of a diopter (compared with 0.25 diopter increments with traditional lenses). Additionally, the lenses are created to account for variations in the prescription across the surface of the lens. Therefore, the lenses are able to be manufactured to not only help you see better but also see across more of your lens.

Furthermore, Optikam decreases measurement mistakes by automating a process that was historically done manually.

What Lens’ Options Does Optikam Demonstrate?

- Anti-reflective coatings minimizing the amount of light that reflects off the surface of your lenses, which reduces glare and eye fatigue

- Thickness/High index lens materials enable the lenses to be up to 50% thinner and lighter than regular plastic lenses.

- Photochromic (transition) lenses automatically darken into sunglasses when you go outside and then quickly return to a clear state indoors.

- Polarized lenses diminish glare from flat, reflective surfaces (like water) and also reduce eye fatigue.

- Tint come in all colors and grades.

Augmented Reality Lens Demonstration

Optikam allows the patient to compare different Free Form and Traditional lens designs in real-time using augmented reality.